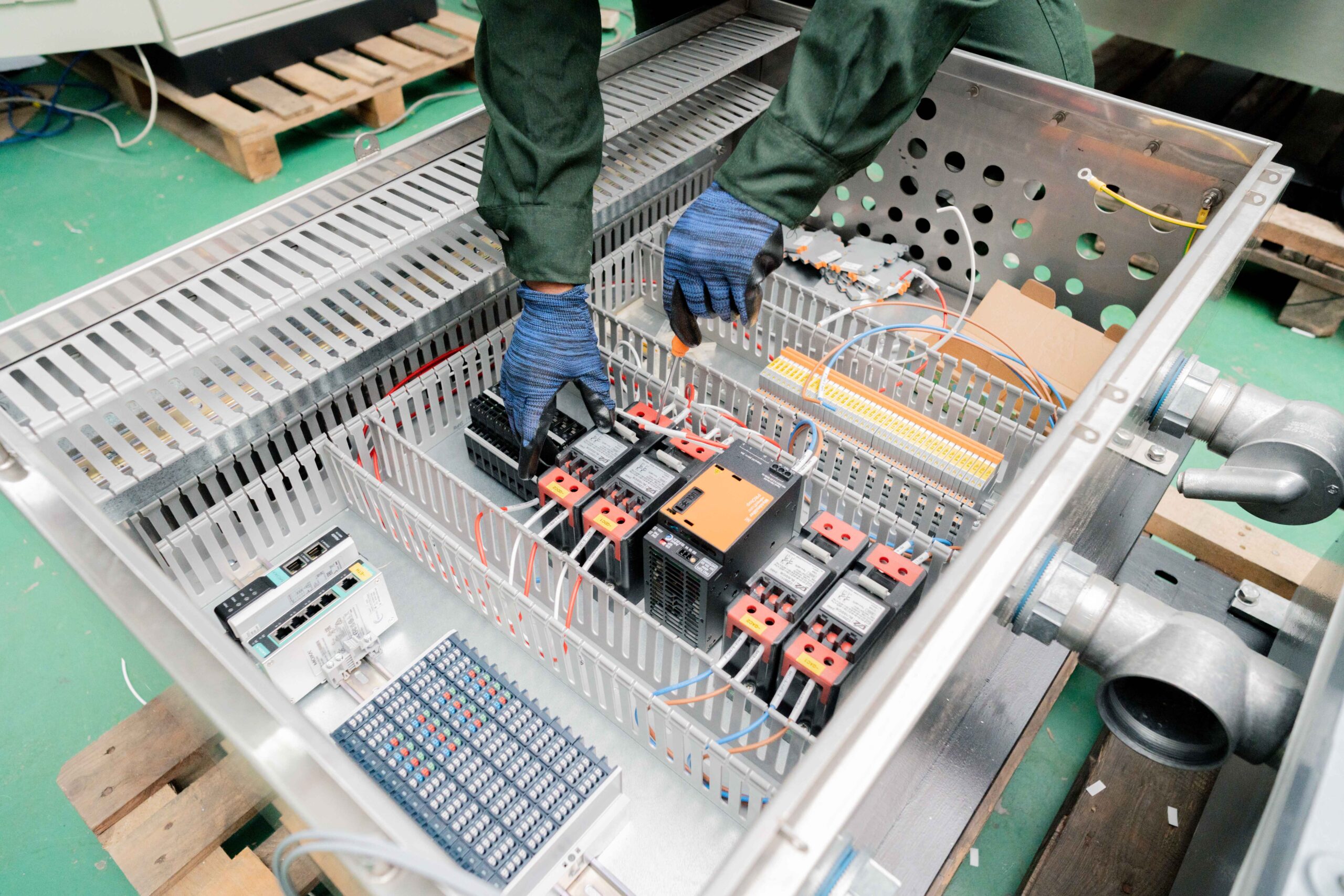

In the realm of industrial automation, electrical controls play a pivotal role in driving efficiency, productivity, and innovation. From assembly lines to power plants, these sophisticated systems orchestrate complex processes with precision and reliability. In this blog post, we’ll explore some advanced applications of electrical controls in various industrial settings.

1. Motor Control Systems:

Electric motors are ubiquitous in industrial machinery, powering everything from conveyor belts to robotic arms. Electrical controls, such as variable frequency drives (VFDs) and motor starters, are used to regulate the speed, direction, and torque of motors, allowing for precise control and energy savings.

2. Process Control Systems:

In industries like chemical processing, pharmaceuticals, and food production, precise control of temperature, pressure, flow, and other variables is critical for ensuring product quality and safety. Programmable logic controllers (PLCs) and distributed control systems (DCS) are employed to monitor and regulate these processes in real-time, enabling tight control and rapid response to changing conditions.

3. Supervisory Control and Data Acquisition (SCADA) Systems:

SCADA systems are used to remotely monitor and control industrial processes and infrastructure, such as power distribution networks, water treatment plants, and oil refineries. These systems integrate data from sensors, meters, and other devices to provide operators with a comprehensive view of the entire operation, facilitating informed decision-making and proactive maintenance.

4. Robotics and Automation:

Robotic systems are revolutionizing manufacturing and assembly processes, offering unparalleled speed, precision, and flexibility. Electrical controls, including motion controllers and programmable automation controllers (PACs), are at the heart of these systems, coordinating the movements of robots and synchronizing them with other equipment to optimize production workflows.

5. Energy Management Systems:

With energy costs on the rise and environmental concerns mounting, industrial facilities are increasingly adopting energy management systems (EMS) to monitor, analyze, and optimize energy usage. Electrical controls, such as smart meters and energy monitoring devices, provide real-time data on energy consumption, enabling companies to identify inefficiencies, implement energy-saving measures, and reduce their carbon footprint.

In summary, electrical controls are indispensable tools for achieving efficiency, reliability, and competitiveness in industrial settings. By harnessing the power of automation, precision control, and data analytics, these advanced systems empower manufacturers to stay ahead in today’s fast-paced and increasingly interconnected world.